Top Info For Choosing Packaging Equipment

Wiki Article

What Are The Differences Between Packaging Machines For Food, Industrial And Cosmetic Products?

Different industries have different packaging requirements. These machines can accommodate large or heavy products as well as smaller, delicate parts. They are typically built with solid construction and the latest technology to ensure accurate and effective packaging.

Food packaging machines- Food packaging equipment are specifically designed to meet the strict hygiene and safety standards in the industry of food. They usually come with temperature control capabilities and easily-maintained surfaces.

Cosmetics packaging machines Cosmetics packaging machines are specifically designed to handle delicate and fragile containers, such as small tubes, vials and bottles. To ensure products are properly packaged, they're often equipped with soft and precise handling systems.

Machines for packaging pharmaceuticals The machines are constructed to meet the rigorous safety and regulatory requirements of pharma. These machines come with sophisticated labeling capabilities as well as tamper-evident seals.

Machines for packaging household products- These machines are equipped to handle a large variety household products, including detergents and cleaning supplies. They often have features like modular packaging configurations, as well as a multi-head filling systems to ensure that household products are packed efficiently and efficiently.

These machines are tailored to each industry's specific needs. Follow the most popular Écosystème for more advice..

What Are The Most Rapid And Effective Packaging Solutions For Industrial Companies

Small Packaging in Industrial Sector- Automated packing lines can be used for small packaging in the industrial sector. Vertical form fill sealing machines, small format packaging machines and multihead weighers aid in increasing efficiency and accuracy during the process of packaging. Automated storage management systems can also be used to optimize the storage and retrieval of small packaging.Palletizing for Long Periods- Robotic palletizing systems can be used to improve the efficiency of the palletizing process, while also reducing the risk of injury to operators. These systems can handle various types of packaging and be programmed to allow palletizing at high speed.

Treatment of small vials as well as fragile bottles Specialized packaging equipment such as blister packaging machines can be employed in the cosmetics and beauty industries to handle tiny vials as well as fragile bottles. They can guarantee that containers and vials are securely packaged and have little handling, thus which reduces the risk of injury.

All cases should be considered when choosing the packaging equipment. It is also recommended to implement a preventative maintenance program to ensure that the equipment continues to perform efficiently and effectively over a long period of time. Read the most popular Productivité for website advice..

Please Describe The Various Machines And Systems Used In The Food And Drink Industry.

Blast Chillers- Blast chillers which are specially designed refrigeration units, rapidly lower the temperature for hot food items to prevent the growth and spread of harmful bacteria. These machines are used in the beverage and food industries to safeguard food products and prolong the shelf life of perishable foods. These solutions can increase effectiveness and maintain the quality of food products.

Packaging cardboard boxes and trays Equipment like tray forgers and case erectors are able to package food items in cardboard boxes and tray. They can design the tray or box and pack it with food items. After that, seal the box by a single, automated procedure.

Shrink Sleeve- Shrink sleeves can be applied to beverages and food containers by using shrink sleeves machines. The shrink sleeve will be placed over the container and then subjected to heat, which causes it to shrink, and then conform to the form of the container. It is a beautiful packaging that is tamper evident and tamper-proof. It is also safe for food.

When selecting the best packaging device for your beverage or food product, you should consider the requirements specific to it. Additionally, the equipment should be designed to comply with the standards for food safety, such as those set by agencies like FDA or USDA. USDA or FDA in order to ensure the products packaged are safe for consumers to eat. Have a look at the best moteurs Omron for blog info..

Wraparound Case Packer Equipped With Feeds That Are Automatic, As Well As Flatbed Magazine

A Wrap-around Case Packer is a type of machine for packaging that is designed to wrap boxes in a wrap-around manner. There are usually automatic feeds that are able to adjust to fit different boxes. The system of feeding is created to load the boxes into the machine at a regular rate, which helps to guarantee efficient operation.The wrap-around case packer is usually able to adapt to various box types, and it can be set up to accommodate various sizes and forms of boxes. This flexibility makes it ideal for various industries and purposes.

The wrap-around casepacker has an adjustable flatbed magazine. This magazine can be adjusted to suit different shapes and sizes of boxes. The machine is able to be used for a wide range of packaging situations without the need to make any modifications or change the tooling.

Alongside its flexibility and convenience, wrap-around case packers are made for efficiency and are usually equipped with modern features like robotics and programmable logic controllers. These features allow the machine to function smoothly and accurately even in production environments.

Overall, a wrap-around case packer that has automatic feeds, an adjustable flatbed magazine, and adaptability to many formats, is a reliable and economical solution to a wide range of packaging requirements as well as helping to improve efficiency and production efficiency in many industrial situations. See the most popular Palettiseurs de bas niveau for more examples..

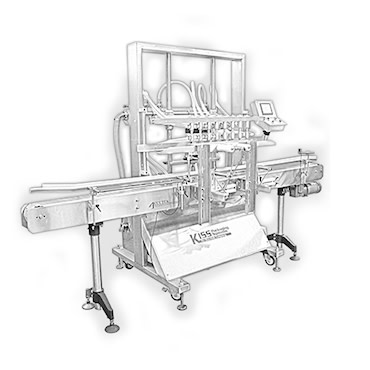

Tailor-Made Automatic Packaging Systems For Cosmetics, Food, Industrial And Pharmaceutical Products As Well As Household Items

Tailor-made packaging systems can be customized to meet the specific requirements of a particular industry. These systems are specifically designed to improve the process of packaging, boost productivity, and meet particular requirements of the industry.

Flexible packaging configurations for the systems may be tailored to meet industry specifics, including the shape, size, and kind of packaging material used and output you want to achieve.

Production processes that are efficient- Tailor-made automated packaging systems are developed to maximize production efficiency and minimize downtime, making them perfect for production in high-volume environments.

High-tech- These systems come with the latest technology, which includes robots that can be programmed with logic controllers and the most advanced sensors to ensure accurate and consistent operation.

Quality Control- Customized, automated packaging systems are developed to monitor the quality of the packaging. They help reduce loss while increasing satisfaction of customers.

These systems offer cost-effectiveness and lower packaging costs. They also deliver high-quality results.

It is evident that custom-designed packaging systems can provide a customized solution to each sector. These systems optimize the packaging process, improve efficiency and decrease overall cost. View the top rated lignes complètes clé en main for blog examples..